Geologic Exploration & Anomaly Detection

Since its inception, REI Drilling has been on the leading edge of directional drilling applications for the mining industry. Our first projects focused on coalbed methane commercialization and degasification, but since those humble beginnings, we have continuously added new approaches and capabilities including geologic exploration, abandoned mine verification, and dewatering. We have used lessons learned from our work in coal to expand into evaporites, metal mining, reclamation, and civil projects, often finding that our unique skillset can open a range of new potential applications for clients. Our approach is the same: talk with the client, determine their needs and what value REI can add, and focus on how to achieve positive results.

Fault and Anomaly Detection

Download Case Studies

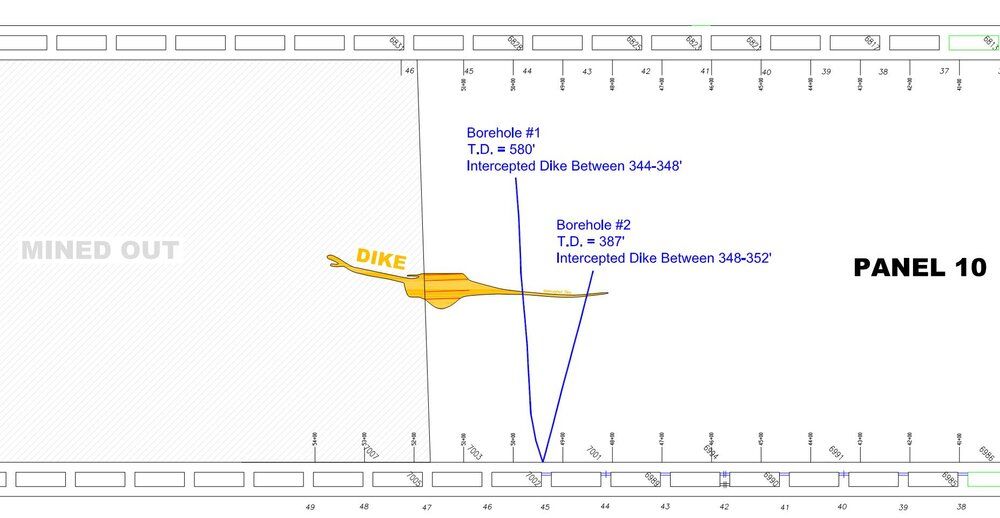

Download Case StudiesREI uses directional drilling and sidetracking to maintain boreholes in the coal seam over distances up to 6,000 feet. Plotting the profile of the borehole from downhole surveys and driller logs provides the mining operation with an indication of coal seam structure. Any discontinuities intercepted during drilling, such as faults, palaeochannels, intrusions, coal burn, etc., are detected by monitoring drilling fluid pressures, changes in thrust, vibration, rate of penetration, and inspection of cuttings. REI will verify the fault location and continue drilling inby the fault to determine the offset and pitch.

Seam Profile Characterization

Download Case Studies

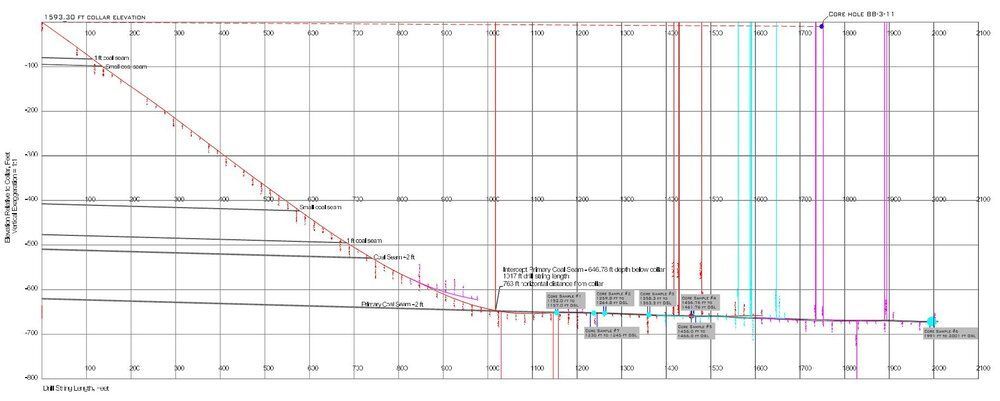

Download Case StudiesDirectional holes provide a wealth of information about bedded deposits. REI uses directional drilling and sidetracking to maintain boreholes in the seam over distances up to 6,000 feet, and by plotting the profile of the borehole from downhole surveys and driller logs, REI provides the mining operation with an indication of seam structure along the full length of the borehole. Sidetracks are developed and intentionally drilled into the roof and floor rock at corresponding drill string lengths to compare elevation data to estimate the seam thickness.

Geophysical Surveys and Geotechnical Drilling

Download Case StudiesREI uses directional drilling to gather geophysical data from hard-to-reach areas of mining operations that would not be possible with traditional non-directional techniques. REI can steer a borehole along a determined alignment and run a post-drilling geophysical survey, including continuous gamma, televiewers, and a range of other tooling. Additionally, REI can collect core samples and perform overcore stress tests to provide geotechnical data, as well as stress data points

Coring

Download Case Studies

Download Case StudiesThrough sidetracking, directional drilling maximizes the amount of data gathered from each corehole while minimizing total footage drilled. Increased borehole design capabilities allow for optimal borehole placement and core retrieval. REI has experience from surface and underground setup locations, so call us for more information to see if directional techniques can improve your exploration program.

Tunnel Alignment

Download Case Studies

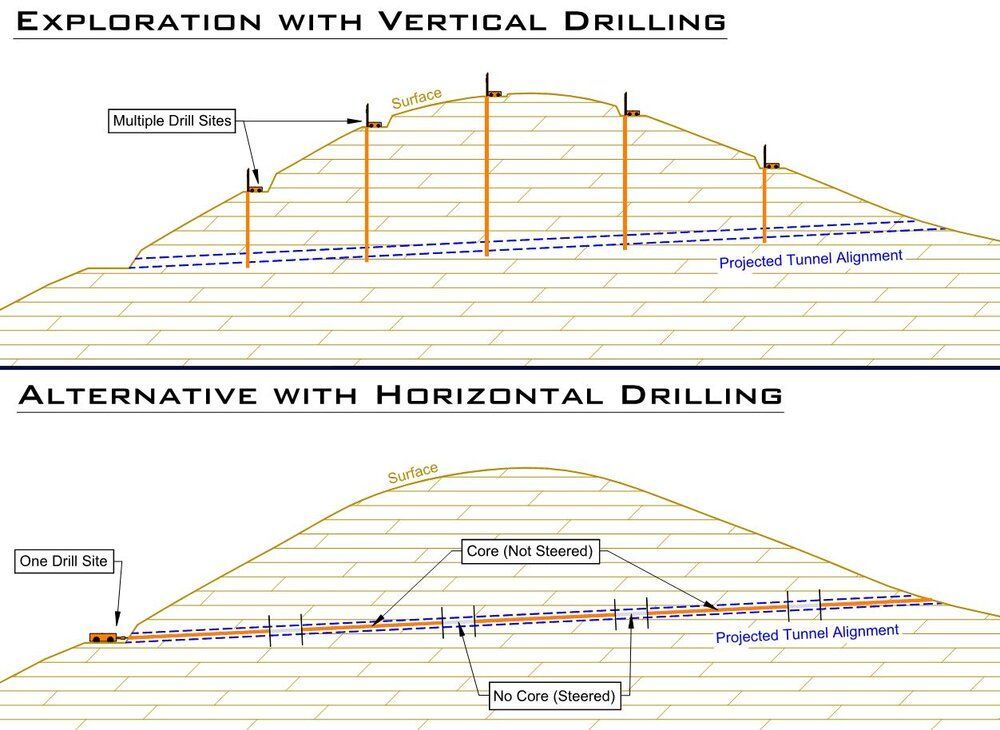

Download Case StudiesGeologic exploration drilling can be performed in advance of a proposed tunnel to gather valuable information about ground conditions and water infiltration. Vertical drilling programs only provide geologic data at specific points along the tunnel alignment and can require extensive permitting and infrastructure investments. Horizontal directional drilling can be implemented as an alternative to gather data along the entire length of the projected tunnel alignment.

Abandoned Well Locating with Magnetic Detection

Download Case StudiesVertical boreholes, such as historic gas wells in advance of mining developments, are often unable to be accessed from the surface. In these cases, horizontal drilling can be employed to verify the locations. REI can develop parallel horizontal boreholes on either side of a magnetic anomaly, and use a magnetic gradiometer to verify the vertical hole location with a high level of accuracy. This novel approach allows mines to locate objects such as vertical well casings, giving the confidence to continue development.

Geophones and Highwall Monitoring

Download Case StudiesREI uses directionally steered holes to place sensors and monitoring equipment in areas where traditional non-directional holes may not be able to reach. With our focus on directional drilling, REI can assist in developing an installation plan using steered boreholes. Applications include slope stability for open pit highwalls and subsistence monitoring for underground caving and full-extraction methods.

Interested in Geologic Exploration & Anomaly Detection services

2 x Fletcher High Thrust Longhole Drills (2-part)

2 x Fletcher High Thrust Longhole Drills (2-part)3 x Fletcher High Thrust Longhole Drills (1-part)

3 x Fletcher High Thrust Longhole Drills (1-part)Acker Big John MPM Drill

Acker Big John MPM Drill2 x VLI 1000 Longhole Drills

2 x VLI 1000 Longhole Drills2 x VLI 3000 Extended Reach Drills

2 x VLI 3000 Extended Reach Drills2 x Versadrill KmN1.4U Underground Drills

2 x Versadrill KmN1.4U Underground Drills1 x Versadrill KmN1.4S Surface Drill

1 x Versadrill KmN1.4S Surface Drill1 x Hagby Onram 1000 Drill

1 x Hagby Onram 1000 DrillJWS-165L Well Service Pump

JWS-165L Well Service PumpDiamec 262-M Low Seam Drill

Diamec 262-M Low Seam DrillLongyear LM-75 Longhole Drill

Longyear LM-75 Longhole Drill

Innovative Directional Drilling Services For The Mining And Civil Industries